Determining the centerline radius for your tube

When it comes to your tube fabrication project, not only do you want to know what tubing is right for you but you also want to determine the centerline radius.

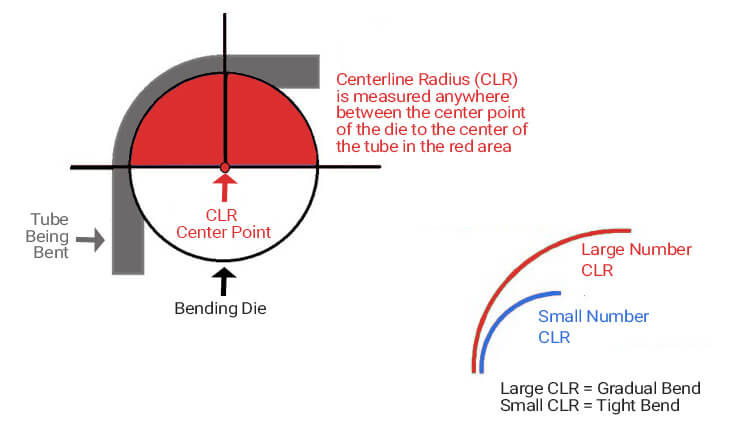

The centerline radius (CLR) is the distance from the center of the bending die to the centerline (axis) of the tube.

Why should you know your CLR?

The CLR should typically measure 2-3X the diameter of the tube (2D or 3D), depending on wall thickness.

It is possible to have a tighter bend radius, even as low as 1D. Choosing below 2D will add tooling cost (more on tooling in upcoming posts).

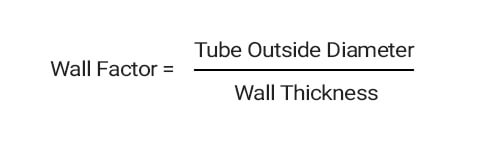

Another consideration in choosing your centerline radius is knowing your wall factor.

Wall Factor

Calculate the wall factor – the ratio between the outside diameter of the tube and its wall thickness.

When the wall factor is lower, the bend is easier to make. If the wall factor is too high, the bend will likely require additional tooling to make it work.

It’s important to have a basic understanding of what is involved in the tube bending process. Identifying your CLR is just one step of the formula.

Questions regarding your project CLR? Leonhardt is happy to consult on your centerline radius needs.