Blog

Home /

Choosing the Right Contract Manufacturer: A Guide for Success

In today's dynamic business world, outsourcing manufacturing processes has become essential for companies aiming to optimize efficiency, cut costs, and concentrate on core competencies. Explore essential factors in selecting the ideal contract to find your perfect partner to maximize business potential.

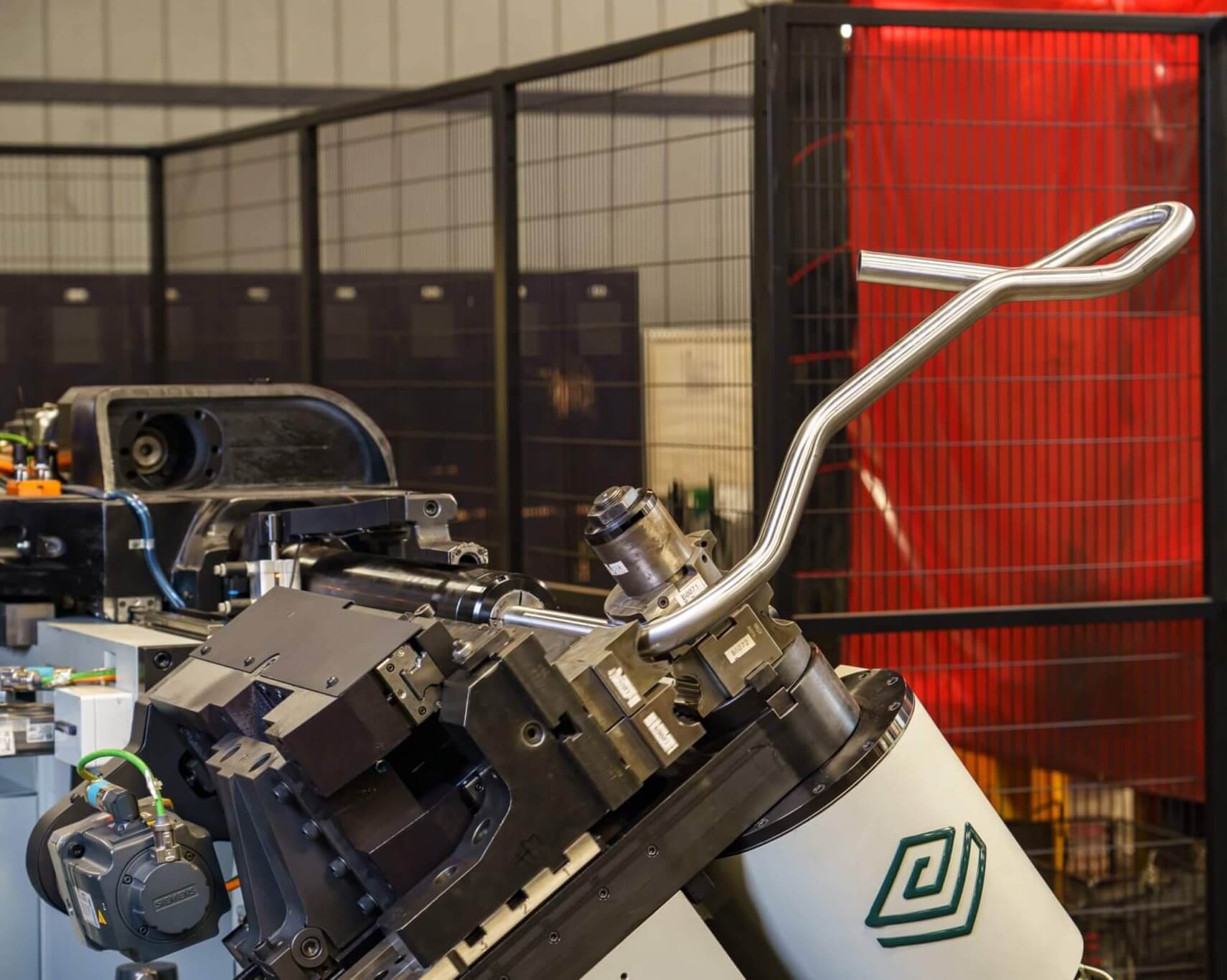

Contract Manufacturing for Tube Bending

Unlock the potential of contract manufacturing for tube bending with our beginner's guide. Learn how this model can save costs, provide expert assistance, and offer unmatched flexibility for your projects. Discover the steps to get started and overcome common challenges, ensuring your venture into contract manufacturing leads to success.

Material Selection: Beyond the Bend in Tube Fabrication

Material selection in metal tube bending is a crucial factor that affects everything from mechanical properties to corrosion resistance, making it essential for industries spanning from furniture design to vehicles.

Ensuring Precision Bent Parts: Romer Arm & Bend Check Fixtures

In the realm of precision manufacturing, the quality of bent parts is paramount across industries like aerospace and automotive. Learn how the Romer Arm and Bend Check Fixtures boost precision and efficiency in manufacturing. Discover when to use each method and how they can work together to guarantee top-notch results.

Right-Hand, Left-Hand, and Multi-Stack Bending: Transforming Metal Tubes with Precision

Right hand, left hand, multi-stack bending of metal tubes is a crucial technique in various industries, enabling the creation of complex and customized components. Mastering this art requires a deep understanding of the process, proper tooling, and precise techniques.

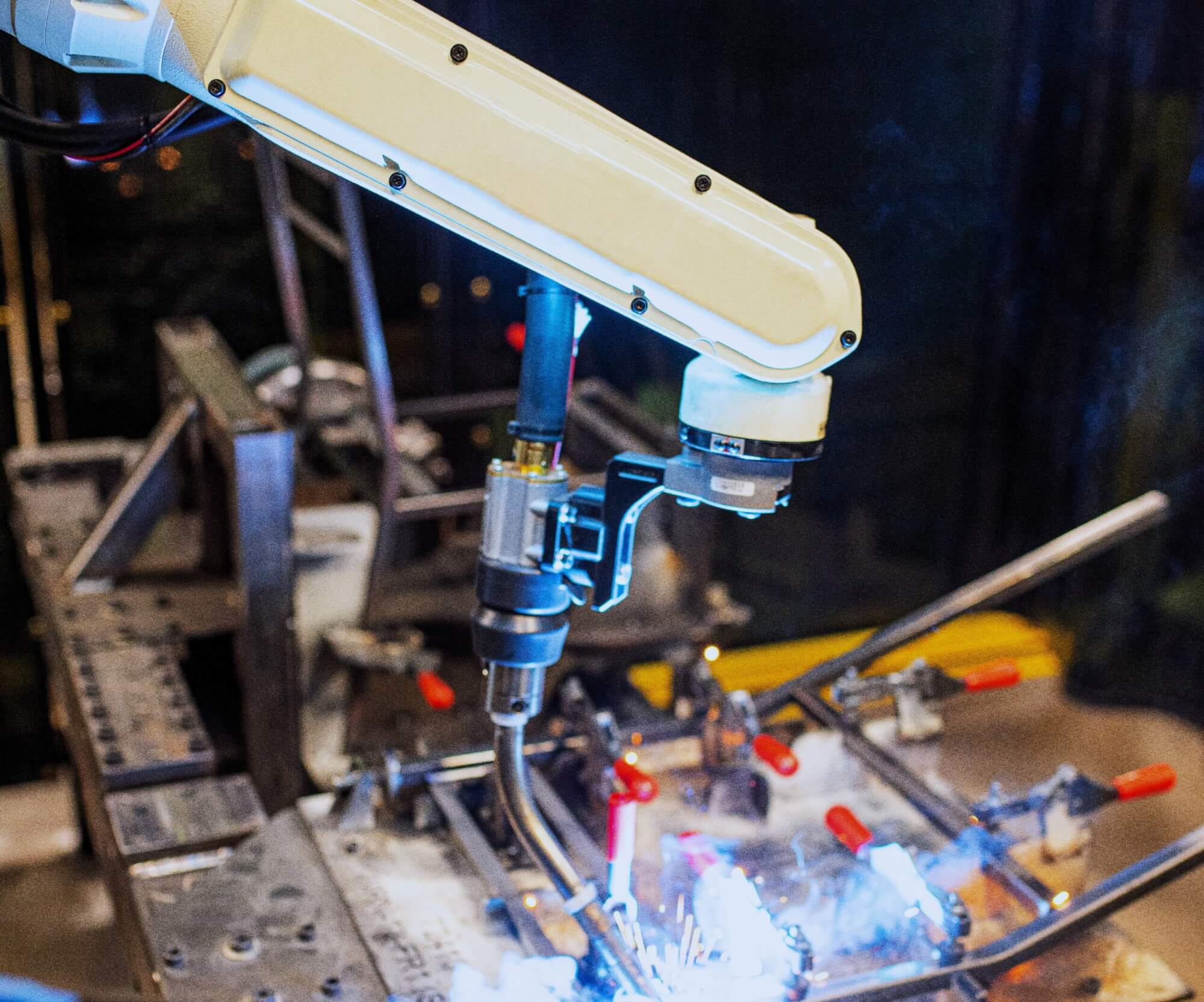

Role of Robotics in Manufacturing, Part 2

Robotics has transformed the manufacturing industry, offering a wide range of benefits to manufacturers worldwide. From automation and precision to safety and flexibility, robots play a vital role in enhancing productivity and efficiency.

The Role of Robotics in Manufacturing

Robotics in manufacturing offers numerous benefits, including increased productivity, improved quality, enhanced safety and more. As technology advances further, robotics is likely to continue playing a pivotal role in transforming and shaping the future of manufacturing. Contact Leonhardt Manufacturing today to learn more about our robotic welding capabilities and how we can help you with your next project.

Welding 101: The different types of welding

Did you know that historians believe the ancient Egyptians developed the earliest forms of welding around 4000 BCE? But it wasn’t until the 18th century that welding really skyrocketed due to the Industrial Revolution. Today, there are several types of welding for various experience levels and applications. Keep reading to find out more. MIG Welding When starting out, welders typically begin with MIG welding since it is considered one of the easiest types to learn.

Why does beautifully made decorative tubing matter?

Tubular steel is used in a variety of industries, including furniture, transportation, medical device, power sports, recreation and industrial just to name a few. It can be beautiful and decorative, simple and functional, or anywhere in between. Decorative tubing, often called ornamental tubing, is purely decorative and not suitable for pipeline applications where fluids are being transported.

Exceptional Quality Control: How to Stand Out from the Rest

Reliable, consistent parts set YOU apart from your competition. That’s why quality management is essential. It ensures error-free and timely delivery of products to your customers. The quality of your product determines the level of trust your customer has for your company and the product you supply. When your products are not delivered on time or have defects, it hurts your company’s reputation.