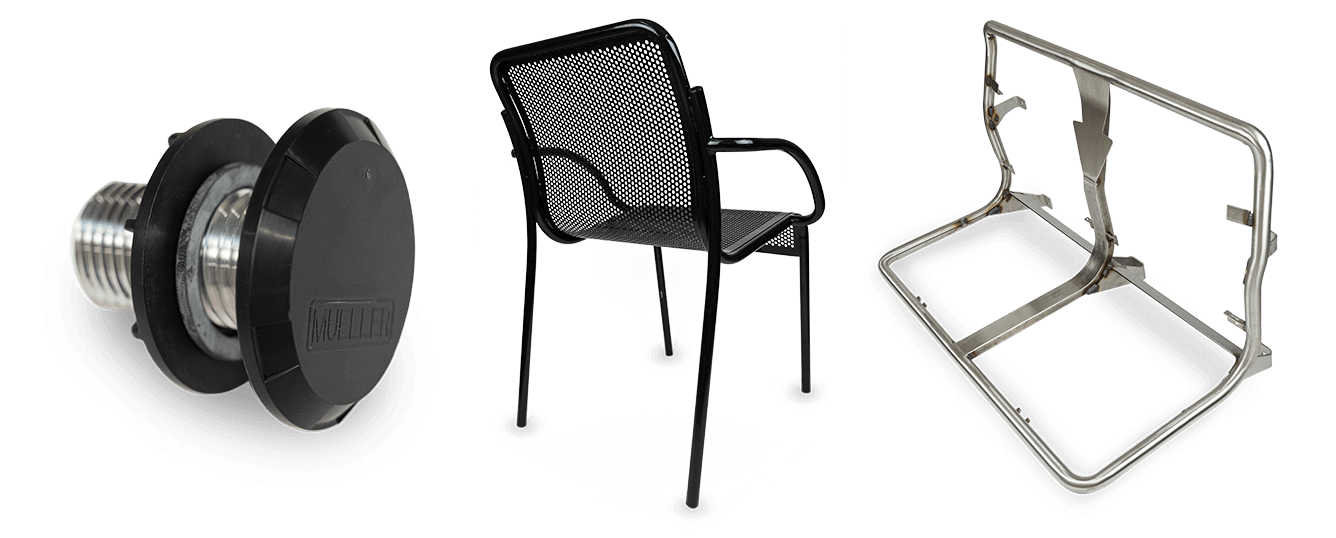

DECORATIVE FABRICATED METAL PRODUCTS

Tubular components with high-quality finishes produced through advanced tube bending, precision fabrication, and controlled metal finishing processes.

CONTRACT MANUFACTURING

From prototyping through full production, manufacturers depend on Leonhardt for tube bending, fabrication, and assembly support across a wide range of manufacturing applications.

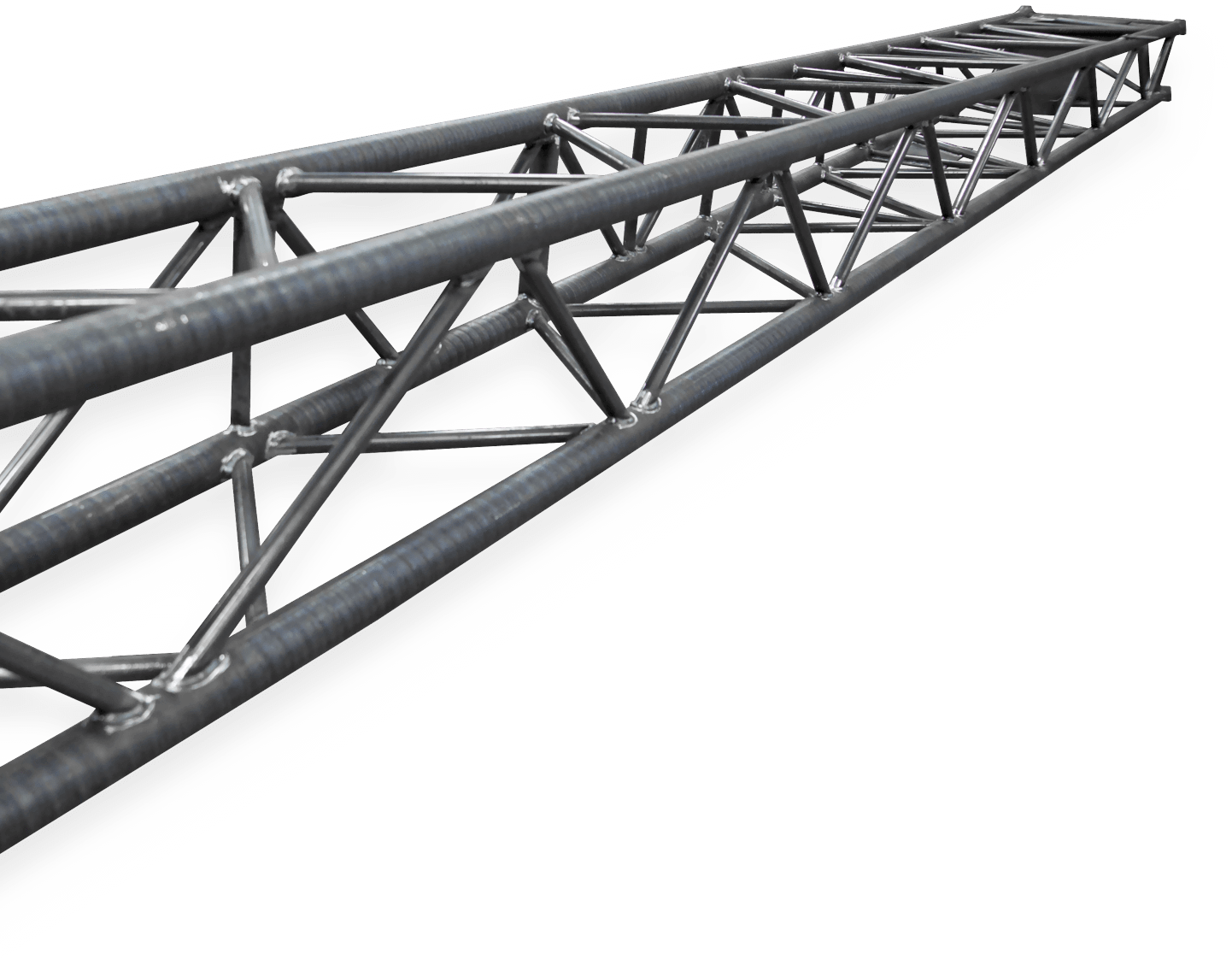

HEAVY DUTY PRODUCTS

Tube bending and metal fabrication supporting complex components and assemblies used in industrial and heavy-duty manufacturing applications.

CAPABILITIES

Leonhardt offers CNC tube bending, sheet metal fabrication, welding, brazing, machining, metal finishing, stamping, and sub-assembly support to produce precision tubular and metal components for manufacturing applications.

NEWS AND UPDATES

Manufacturing Supplier Scorecard

Learn how a supplier scorecard can help your team uncover hidden risks in manufacturability, capacity, and communication before a purchase order is ever issued.

The Manufacturer’s Guide to On-Time Delivery (OTD)

Improve on-time delivery by defining OTD clearly, measuring supplier performance, diagnosing late shipments, and building a more stable, reliable supply chain.

How to Calculate the Weight of Steel Tubing

Learn how to calculate steel tube weight quickly and accurately with formulas for round, square, and rectangular tubing — plus Excel-ready equations and pro tips from Leonhardt Manufacturing.

WE TAKE QUALITY SERIOUSLY

Excellence in Manufacturing

From fabrication support for production programs to supply chain coordination and manufacturing efficiency, Leonhardt helps manufacturers maintain stable production, reduce disruption risk, and support long-term operational performance.