Right-Hand, Left-Hand, and Multi-Stack Bending: Transforming Metal Tubes with Precision

Metal tube bending isn’t just a process; it’s an art that shapes the world around us. From the sleek curves of a car’s exhaust system to the sturdy frames of aerospace structures, bending metal tubes into perfect angles is a blend of science and skill. In this exploration, we’ll unravel the intricacies of right-hand, left-hand, and multi-stack tube bending – techniques that are as fascinating as they are fundamental in various industries. Join us on this journey through the bends and curves of metal tubes, where precision meets innovation.

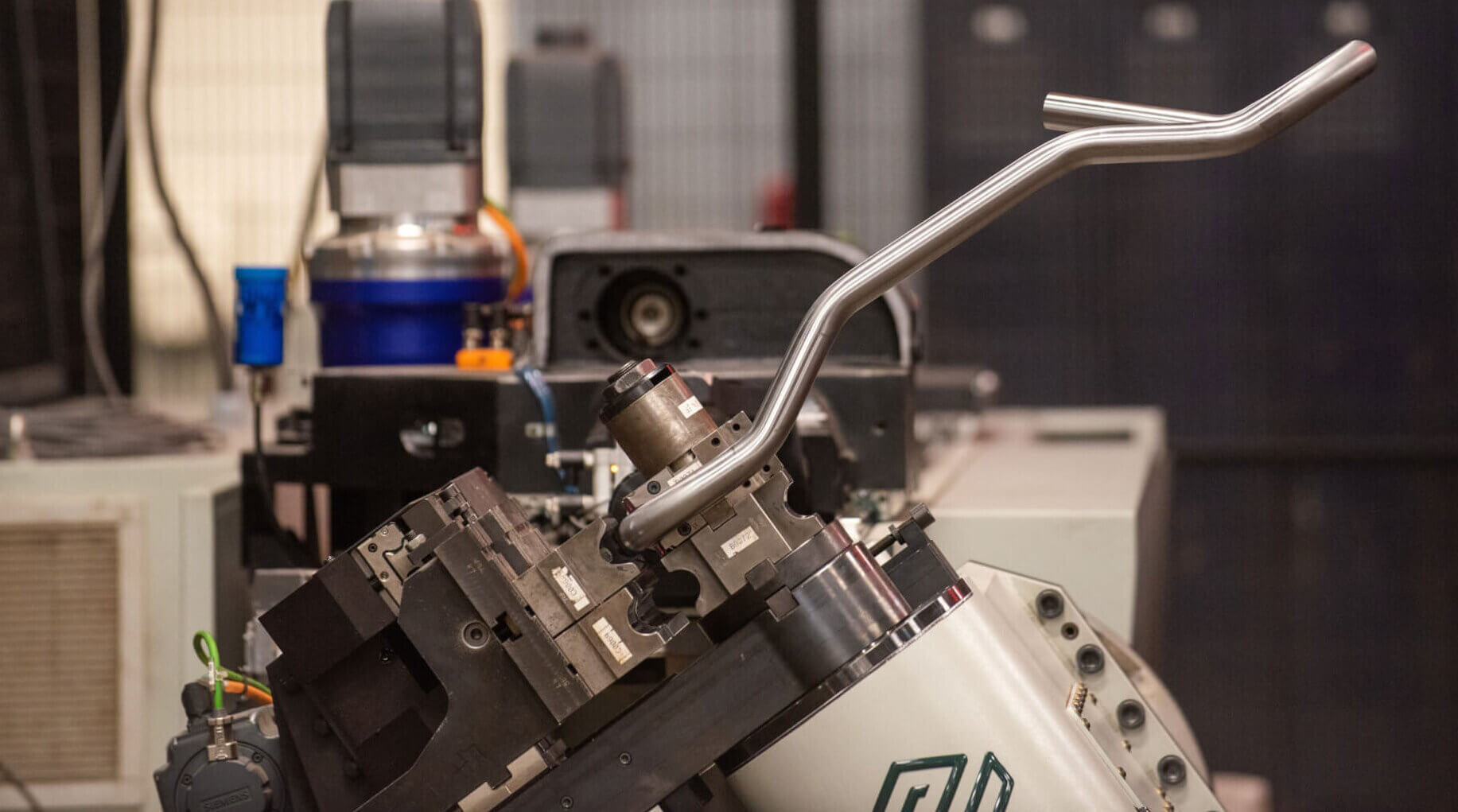

Essential Techniques in Metal Tube Bending

Right Hand Bending: Definition and Applications

Right hand bending involves bending the tube in a clockwise direction, which results in the outer side of the bend experiencing compression, while the inner side undergoes tension. The technique is commonly used when the bend radius is small, and it offers greater control and precision over the bend angle. Right hand bending is ideal for applications where tight tolerances and accuracy are critical.

Left Hand Bending: Characteristics and Uses

Conversely, left hand bending involves bending the tube counterclockwise where the outer side experiences tension and the inner side compression. Left hand bending is suitable for situations where the bend radius is larger or when specific designs require bends in the opposite direction. Just like right hand bending, it requires skill and precision to achieve accurate results.

Multi-Stack Bending: A Precision Approach

Multi-stack bending is a sophisticated technique used for complex tube bending projects. This method involves bending a tube in multiple stages, with each bend carefully calculated and executed to achieve the desired final shape. This technique is commonly used when the required bend angles are intricate, and demands a high level of expertise and precision.

Application in Various Industries

The versatility of right hand, left hand, multi-stack tube bending makes it suitable for a wide range of applications across multiple industries:

Furniture and Interior Design: Aesthetic and Functional Aspects

Metal tube bending has found its place in the world of furniture manufacturing, where it is used to create unique and aesthetically pleasing designs. Whether it’s crafting the frame of a modern chair or a minimalist table base, these techniques offer endless possibilities for creative designers.

Automotive Industry: Enhanced Performance and Safety

The automotive sector is at the forefront of innovation when it comes to metal tube applications. Right Hand, Left Hand, and Multi-Stack Tube Bending play a pivotal role in creating exhaust systems, roll cages, and chassis components. These bending techniques enable the creation of strong and lightweight roll cages, enhancing vehicle safety.

Recreational Off-Road Vehicles: Enhanced Handling and Durability

Different bending methods are used in the design and manufacturing of various components, including handlebars, chassis frames, and suspension systems. Not only does it contribute to the overall functionality but also enhances the rider’s overall experience by providing improved handling and durability, making outdoor adventures more enjoyable and safe.

Aerospace and Aviation: Precision in Structural Components

The aerospace and aviation sectors rely heavily on metal tube bending for fabricating aircraft frames, hydraulic systems, and fuel lines. By employing precise bending techniques, these industries can reduce weight, enhance fuel efficiency, and ensure the structural integrity of vital components.

Medical Equipment: Customized and Accurate Manufacturing

The medical industry relies on metal tube bending for manufacturing various types of medical equipment, including surgical instruments, bed frames, and mobility aids. These techniques allow for the creation of custom-shaped tubing that fits perfectly within medical devices, ensuring accurate functionality and patient comfort.

Key Considerations in Metal Tube Bending

Achieving precise and consistent results in right hand, left hand, multi-stack bending requires expertise and attention to detail.

- Material Selection: Impact on Bending Process

The choice of material plays a significant role in the tube bending process. Different metals have varying properties, which can affect the ease and quality of the bend.

- Bend Radius: Determining the Curve’s Nature

The bend radius determines how sharp or gradual the bend will be. Smaller bend radii are used for tight curves, while larger radii are employed for gentler bends.

- Tube Diameter: Influence on Bending Force

The diameter of the tube affects the force required for bending. Larger diameter tubes may require more force and specialized equipment.

- Tooling and Equipment: Ensuring Precision and Efficiency

Precision bending requires specialized tooling and equipment, such as mandrels, dies, and bending machines, designed to accommodate various tube sizes and materials.

Advantages of Advanced Bending Techniques

The adoption of advanced bending techniques, such as right hand, left hand, and multi-stack tube bending, offer a multitude of advantages that cater to a wide range of industries and applications. These techniques go beyond the conventional methods of tube bending and open up a realm of possibilities for designers, manufacturers, and engineers. Let’s explore these advantages in detail.

Design Freedom and Creativity

It allows for the creation of intricate and custom shapes, giving designers greater freedom in their designs.

Reduced Welding and Enhanced Joint Strength

Complex shapes can often be achieved without the need for additional welding, reducing the risk of weak joints and saving time and costs.

Improved Strength and Durability of Tubes

Multi-stack bending minimizes the risk of wrinkles and distortion in the tube, resulting in a stronger and more reliable end product.

Precision and Repeatability in Production

With the right tooling and techniques, multi-stack bending can achieve high levels of precision and repeatability.

The Growing Significance of Tube Bending Techniques

Right hand, left hand, multi-stack bending of metal tubes is a crucial technique in various industries, enabling the creation of complex and customized components. Mastering this art requires a deep understanding of the process, proper tooling, and precise techniques.

Leonhardt Manufacturing’s Expertise and Services

At Leonhardt Manufacturing, we specialize in tube bending and fabrication, leveraging our expertise to deliver high-quality solutions for our customers. Whether you need right hand, left hand, or multi-stack tube bending, we have the knowledge and capabilities to meet your specific requirements.

Contact us today to learn more about our tube bending services and how we can assist with your next project.