Ensuring Precision Bent Parts: Romer Arm & Bend Check Fixtures

In the realm of precision manufacturing, the quality of bent parts is paramount across industries like aerospace and automotive. Learn how the Romer Arm and Bend Check Fixtures boost precision and efficiency in manufacturing. Discover when to use each method and how they can work together to guarantee top-notch results.

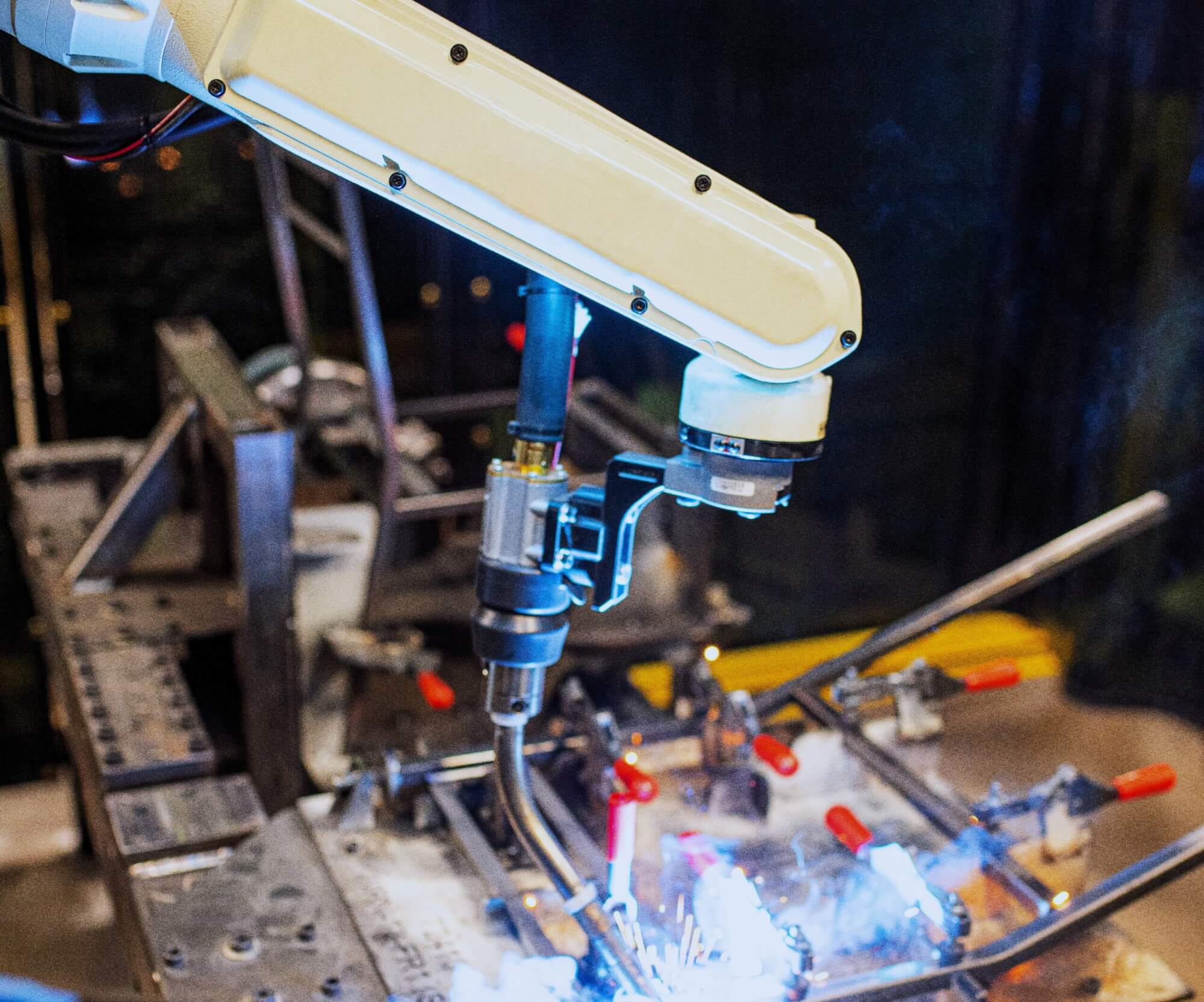

Role of Robotics in Manufacturing, Part 2

Robotics has transformed the manufacturing industry, offering a wide range of benefits to manufacturers worldwide. From automation and precision to safety and flexibility, robots play a vital role in enhancing productivity and efficiency.

The Role of Robotics in Manufacturing

Robotics in manufacturing offers numerous benefits, including increased productivity, improved quality, enhanced safety and more. As technology advances further, robotics is likely to continue playing a pivotal role in transforming and shaping the future of manufacturing. Contact Leonhardt Manufacturing today to learn more about our robotic welding capabilities and how we can help you with your next project.

Exceptional Quality Control: How to Stand Out from the Rest

Reliable, consistent parts set YOU apart from your competition. That’s why quality management is essential. It ensures error-free and timely delivery of products to your customers. The quality of your product determines the level of trust your customer has for your company and the product you supply. When your products are not delivered on time or have defects, it hurts your company’s reputation.

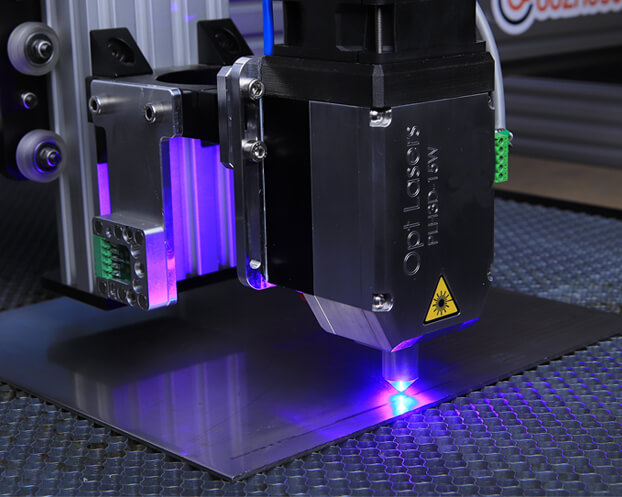

The top 5 benefits of 3D printing in manufacturing

3D printing has revolutionized manufacturing and development. Also referred to as additive manufacturing, 3D printing involves combining multiple layers of a material until you successfully create a 3D printed model. It has become a popular choice among manufacturers due to its innovative benefits that complement traditional manufacturing. While manufacturing companies often use other tools and machines to convert raw materials into finished products, 3D printers offer several unique benefits such as lower costs and waste reduction. Here are the top five advantages to 3D printing in the manufacturing industry.

World-Class Supplier Vs Machine Shop

At Leonhardt Manufacturing, it’s important our customers see us as an extension of their business and get the service they need from all departments. We ensure our sales, engineering, quality, production and customer service are always responsive and understand the goals and needs of each of their counterparts. For us, making the initial sale is just the very beginning of a long relationship. We like to measure our time with customers in decades, not years.