The top 5 benefits of 3D printing in manufacturing

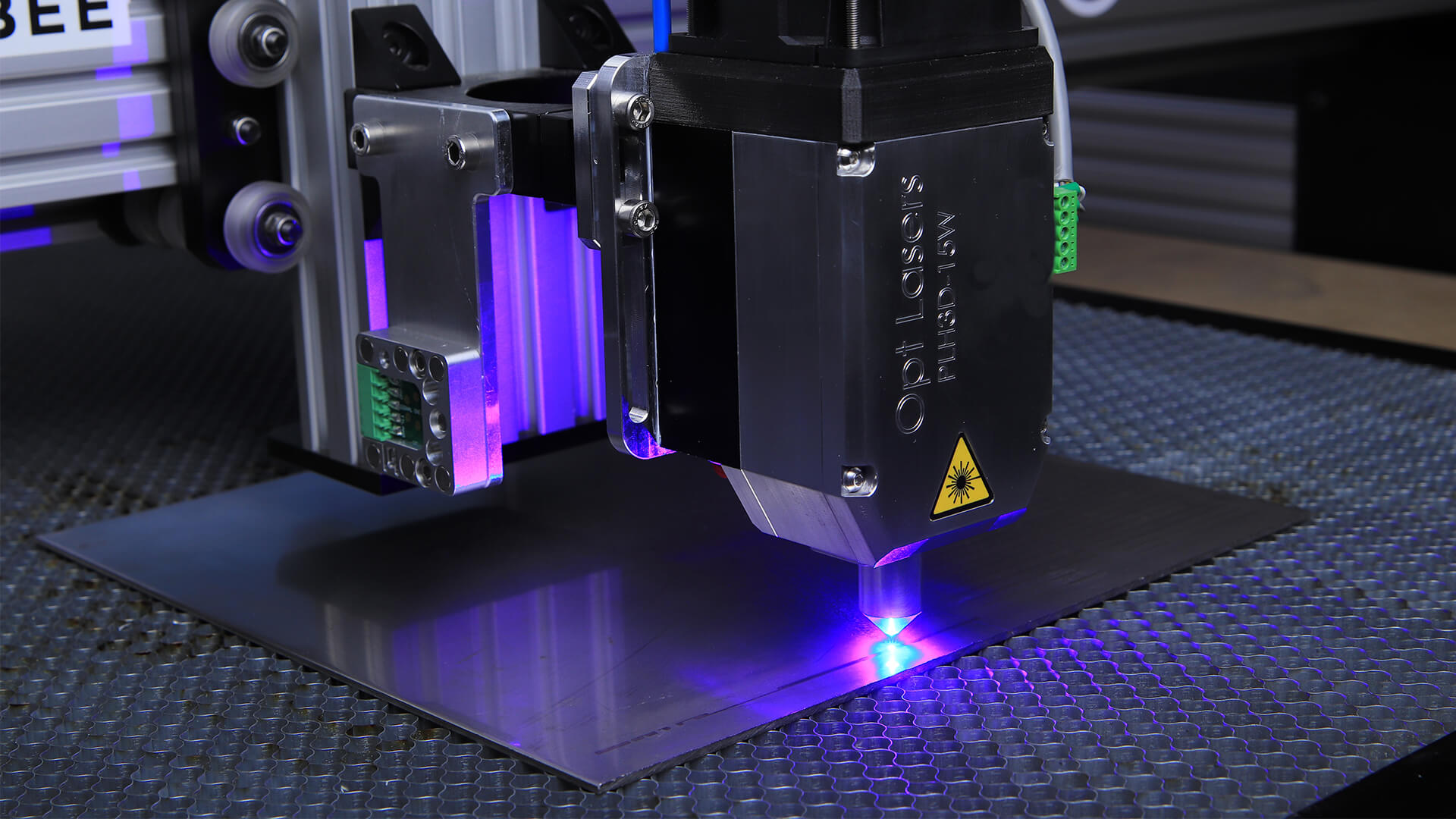

3D printing has revolutionized manufacturing and development. Also referred to as additive manufacturing, 3D printing involves combining multiple layers of a material until you successfully create a 3D printed model.

It has become a popular choice among manufacturers due to its innovative benefits that complement traditional manufacturing.

While manufacturing companies often use other tools and machines to convert raw materials into finished products, 3D printers offer several unique benefits such as lower costs and waste reduction.

Here are the top five advantages to 3D printing in the manufacturing industry.

Fast Prototyping

Manufacturing companies can both design and build prototypes of products more quickly with 3D printers. Before a manufacturing company can mass-produce a product, it must build a prototype. Luckily, 3D printing supports rapid prototyping. Manufacturing companies can quickly design and build prototypes, allowing them to move promptly on their new products.

Decrease of Tooling Costs

Manufacturing engineers design special parts like tools and fixtures to solve challenges in the factory. Since each tool is often custom-made, they can be extremely costly and time consuming to make. Creating new tools to replace broken ones can also mean lost manufacturing time, so reducing the time to replace tools can significantly reduce costs. 3D-printed tools can be replaced in hours rather than days and today’s high-strength plastics are strong, lightweight and less expensive.

Waste Reduction

In several manufacturing facilities, parts start out as a solid block of aluminum or steel, this is known as subtractive manufacturing. Different tools remove material until the final part emerges. The problem with this type of manufacturing is the waste generated during the process. Pieces need to be collected, cleaned and recycled, adding both time and cost. Parts that reduce heat and friction during machining are also costly and require recycling. The 3D printing process eliminates much of this clean-up, ultimately saving time and reducing waste. 3D printers also produce less waste than other tools and machines used in the manufacturing industry. Most 3D printers work from a CAD file, therefore, only releasing material in areas where it’s needed. Also, with a 3D printer, manufacturing companies can achieve a more efficient production process that minimizes waste.

Fewer Risks

When businesses can confirm a design before committing it to production, it helps to remove the risk of errors, wasted materials and money. Creating products with 3D printing makes it easier for manufacturers to redesign of a prototype or alter something that has been created rather than using a traditional method.

When there is a need for design change, there won’t be much loss in terms of cost and time. This significantly reduces the risk of failure.

Strong and Durable Products

3D printers can build products using a range of different strong and durable materials. The strength and durability is highly dependent upon the material from it’s constructed. Polymer, for instance, is frequently used in 3D printers and it’s typically heated in the 3D printer. Once dry, the material hardens to create a strong and durable product.

There’s no way about it, 3D printing has changed manufacturing. With the unparalleled ability to increase speed-to-market, lower costs and customize specialty parts, it is driving innovation and sparking new technologies. Considering how large the impact has been since its debut, expect the benefits of 3D printing to keep expanding in the future.

Learn more about Leonhardt Manufacturing and how we can help your business with your next project.