Ensuring Precision Bent Parts: Romer Arm & Bend Check Fixtures

Ensuring precision bent parts is essential in the world of manufacturing, where the quality and accuracy of every component matter. Bent parts, in particular, play a crucial role in various industries, from aerospace to automotive. Ensuring that these parts meet the highest standards of quality is paramount. In this blog post, we’ll delve into the technical aspects of two common methods used for inspecting bent parts: the Romer Arm & Bend Check Fixtures.

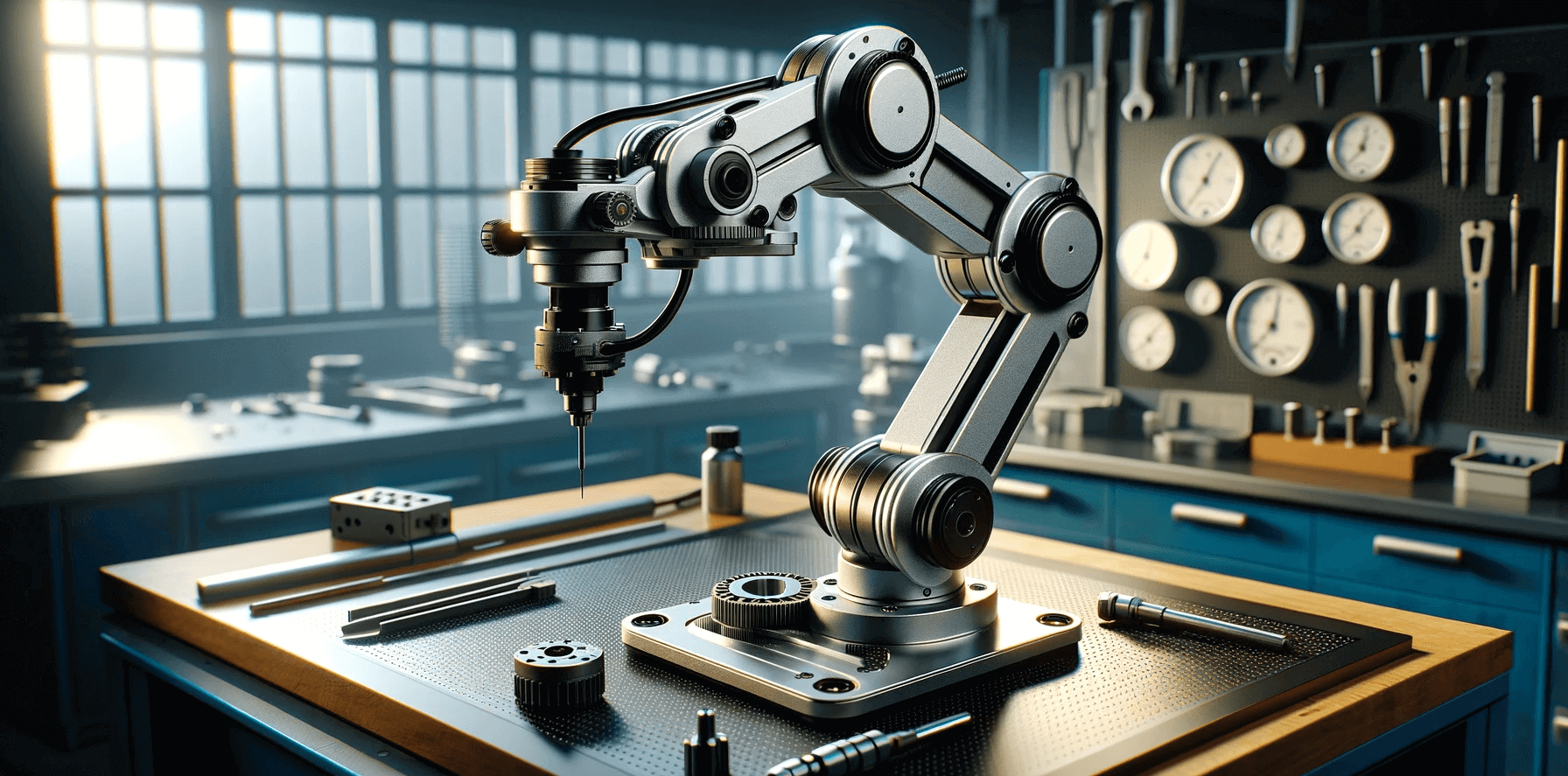

Romer Arm: A Precision Measurement Tool

The Romer Arm, also known as a portable CMM (Coordinate Measuring Machine), is a versatile and advanced measurement tool used to measure the geometry of physical objects. It has gained popularity in industries requiring precision inspections. Here’s how it works:

Precision and Flexibility

- 3D Measurement: The Romer Arm is capable of capturing complex 3D shapes with high precision. This is particularly useful for components with intricate bends.

- Portability: Unlike stationary CMMs, the Romer Arm can be moved around easily, allowing checks performed directly on the production floor.

Speed and Efficiency

- Rapid Data Collection: The arm quickly gathers data points, significantly reducing the time needed for measurement.

- Real-Time Feedback: As it provides immediate results, adjustments can be made on the spot, ensuring a faster turnaround.

However, while the Romer Arm is a powerful tool for measuring and inspecting complex shapes, it may not always be the most suitable choice for bent parts, especially when large quantities need to be checked rapidly.

Bend Check Fixtures: The Customized Approach

Bend Check Fixtures, on the other hand, are specialized tools designed specifically for the inspection of bent parts. These fixtures are tailored to the geometry of the part, ensuring a perfect fit. Here’s how they work:

Tailored to Specifications

Custom Design: Each fixture is designed to match the exact dimensions and contours of a specific part, ensuring a perfect fit.

Custom Design: Each fixture is designed to match the exact dimensions and contours of a specific part, ensuring a perfect fit.- Consistent Quality: By using these fixtures, we can quickly verify if a part meets the predefined standards, maintaining consistency across batches.

Cost-Effectiveness

- Reduced Inspection Time: Once a fixture is set up, checking parts becomes a simple task,leading to reduced inspection time.

- Long-Term Use: These fixtures can be used repeatedly, making them a cost-effective solution for long production runs.

Romer Arm vs. Bend Check Fixtures: Complementary Techniques

At Leonhardt Manufacturing, we often use both the Romer Arm and bend check fixtures in tandem. While the Romer Arm offers unparalleled flexibility and precision, bend check fixtures provide a fast and efficient way to ensure consistency in mass-produced parts. By employing both methods, we can cater to a wide range of customer needs, from one-off prototypes to large-scale production runs.

Leonhardt Manufacturing’s Commitment to Quality & Precision

The combination of the Romer Arm & bend check fixtures embodies our commitment to quality and precision at Leonhardt Manufacturing. By integrating these advanced techniques into our process, we ensure that every bent part we produce meets the highest standards of accuracy and quality. For our clients, this means reliable and superior products, every time.

Stay tuned to our blog for more insights into the world of precision metal fabrication and how we at Leonhardt Manufacturing continue to push the boundaries of quality and innovation.