Blog

Home /

What is poor tooling costing you?

Continuing with our Tooling Blog Series, have you thought about the potential consequences to your project when it comes to poor-quality tooling? Late deliveries? Line stoppage? Good tool design will also take into account the need to adjust for: Part-to-part variation, Future design changes, Material and process tolerances, Ergonomics - the human factor

How will my tooling be certified, calibrated and maintained?

The next topic in our tooling blog series addresses maintenance. How will your supplier do the initial buy-off and ongoing maintenance of your tools? Some things to consider: Do they have a formal process for certifying new tools and doing an initial run-off? PPAP, Gage R&R, capability studies In the case of inspection fixtures, does the supplier have an ongoing calibration process?

Tooling Specs: Why you should care

This week on Tooling Tuesday, we answer why tooling specs are so important. As a rule, in our business tooling is usually a means to an end. Call it a "necessary evil." Our customers are primarily interested in an ongoing supply of tubular products that meet their quality, cost and delivery requirements.

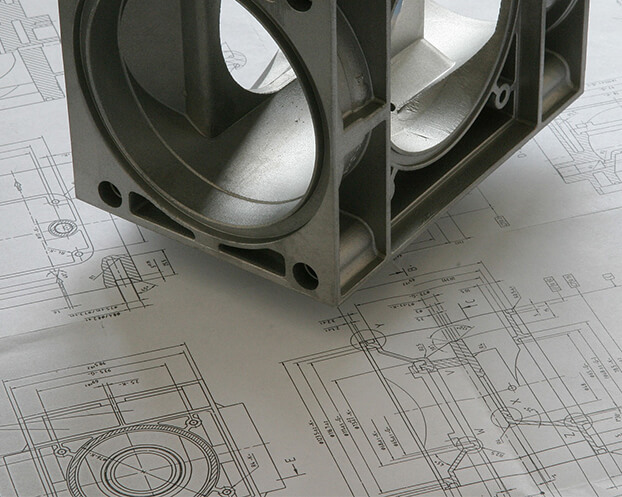

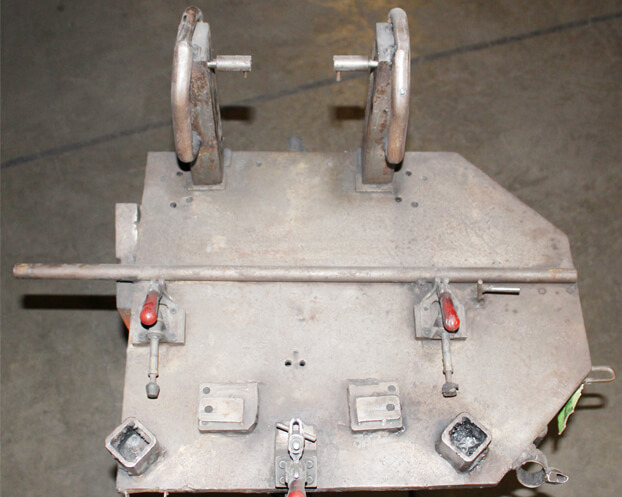

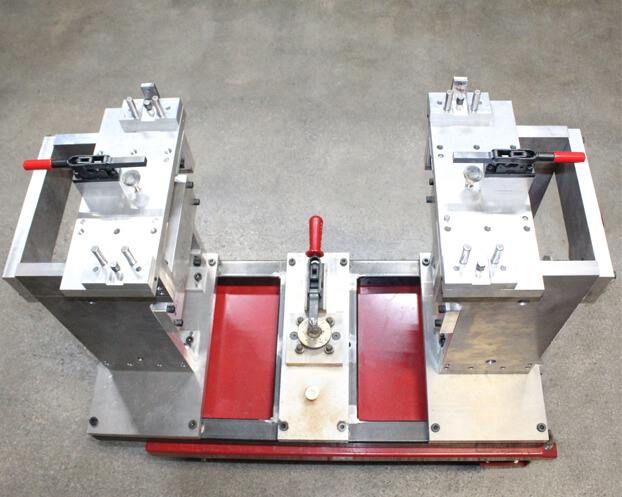

Professionally designed tooling vs on the fly

Continuing our discussion on tooling, this week we are taking a look at some of the fixtures. Is the tooling professionally designed and built by tooling experts, or is it something tacked together "on the fly" by welders in the shop?

Are you paying enough for tooling?

The upfront costs and risks associated with spending money on tooling are usually easy to quantify. The ongoing, perpetual costs of poor-quality tooling are often less well-understood. Its effect on quality and delivery can be the proverbial "death by a thousand cuts." Here are 5 questions every buyer should ask their suppliers before evaluating tooling costs:

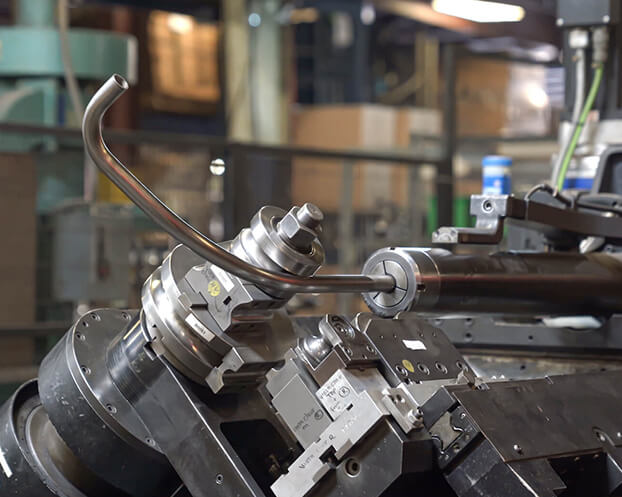

Determining the centerline radius for your tube

When it comes to your tube fabrication project, not only do you want to know what tubing is right for you but you also want to determine the centerline radius. The centerline radius (CLR) is the distance from the center of the bending die to the centerline (axis) of the tube. Why should you know your CLR? The CLR should typically measure 2-3X the diameter of the tube (2D or 3D), depending on wall thickness.

How to choose the right tube for you

Tubes can come in different shapes – round, square, rectangular or oval. But how do you know which is the right one for your project? Metal tubes are generally fabricated from steel, stainless steel, aluminum, brass and copper. These types of tubes can easily be bent into shape without the need for elbows or other fittings. Before you begin any tube bending project, it is important to think about what you need your product to do.

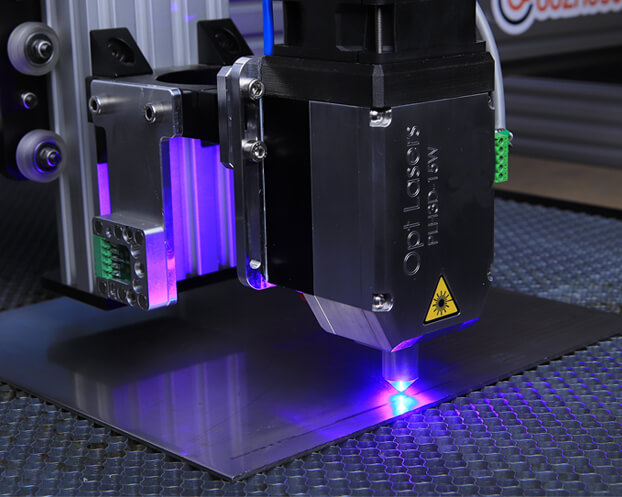

The top 5 benefits of 3D printing in manufacturing

3D printing has revolutionized manufacturing and development. Also referred to as additive manufacturing, 3D printing involves combining multiple layers of a material until you successfully create a 3D printed model. It has become a popular choice among manufacturers due to its innovative benefits that complement traditional manufacturing. While manufacturing companies often use other tools and machines to convert raw materials into finished products, 3D printers offer several unique benefits such as lower costs and waste reduction. Here are the top five advantages to 3D printing in the manufacturing industry.

Have a seat … World-class furniture companies depend on Leonhardt Manufacturing

Chrome plated, powder coated, brushed stainless, carbon steel, low or high volume, batch or JIT … Leonhardt Manufacturing continually exceeds the expectations of a variety of world-class brands in the furniture industry. Our in-house fabrication skills involve CNC rotary and variable radius bending, robotic and manual mig and tig welding, CNC machining and polishing and metal finishing. But what really sets us apart is our ability to deliver highly cosmetic finishes to customers with demanding aesthetic requirements. For these customers, it’s not just a metal fabrication. It’s art!

World-Class Supplier Vs Machine Shop

At Leonhardt Manufacturing, it’s important our customers see us as an extension of their business and get the service they need from all departments. We ensure our sales, engineering, quality, production and customer service are always responsive and understand the goals and needs of each of their counterparts. For us, making the initial sale is just the very beginning of a long relationship. We like to measure our time with customers in decades, not years.