Professionally designed tooling vs on the fly

Continuing our discussion on tooling, this week we are taking a look at some of the fixtures.

Is the tooling professionally designed and built by tooling experts, or is it something tacked together “on the fly” by welders in the shop?

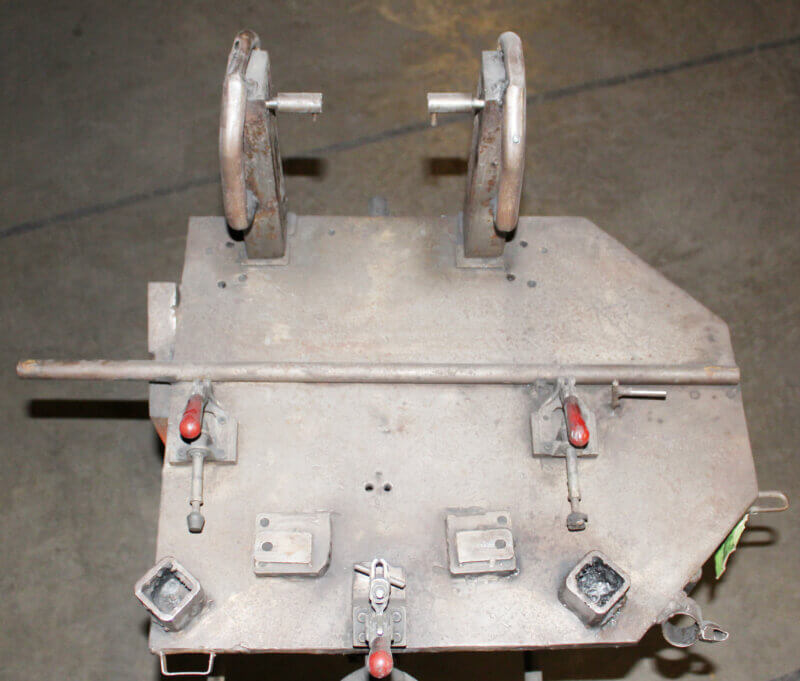

Fixture 1

Useful for very low volume, quick “one-off” jobs

Useful for very low volume, quick “one-off” jobs

- Tacked together by a welder using sample parts and whatever they could find lying around

- No adjustability

- No certification or calibration. If something changes or it’s damaged, there’s no way to get back to its original condition

- No inventory tracking or maintenance plan

- Components are not standard “off the shelf”

- Nothing is straight, flat, square, round … no GD&T or tolerances considered

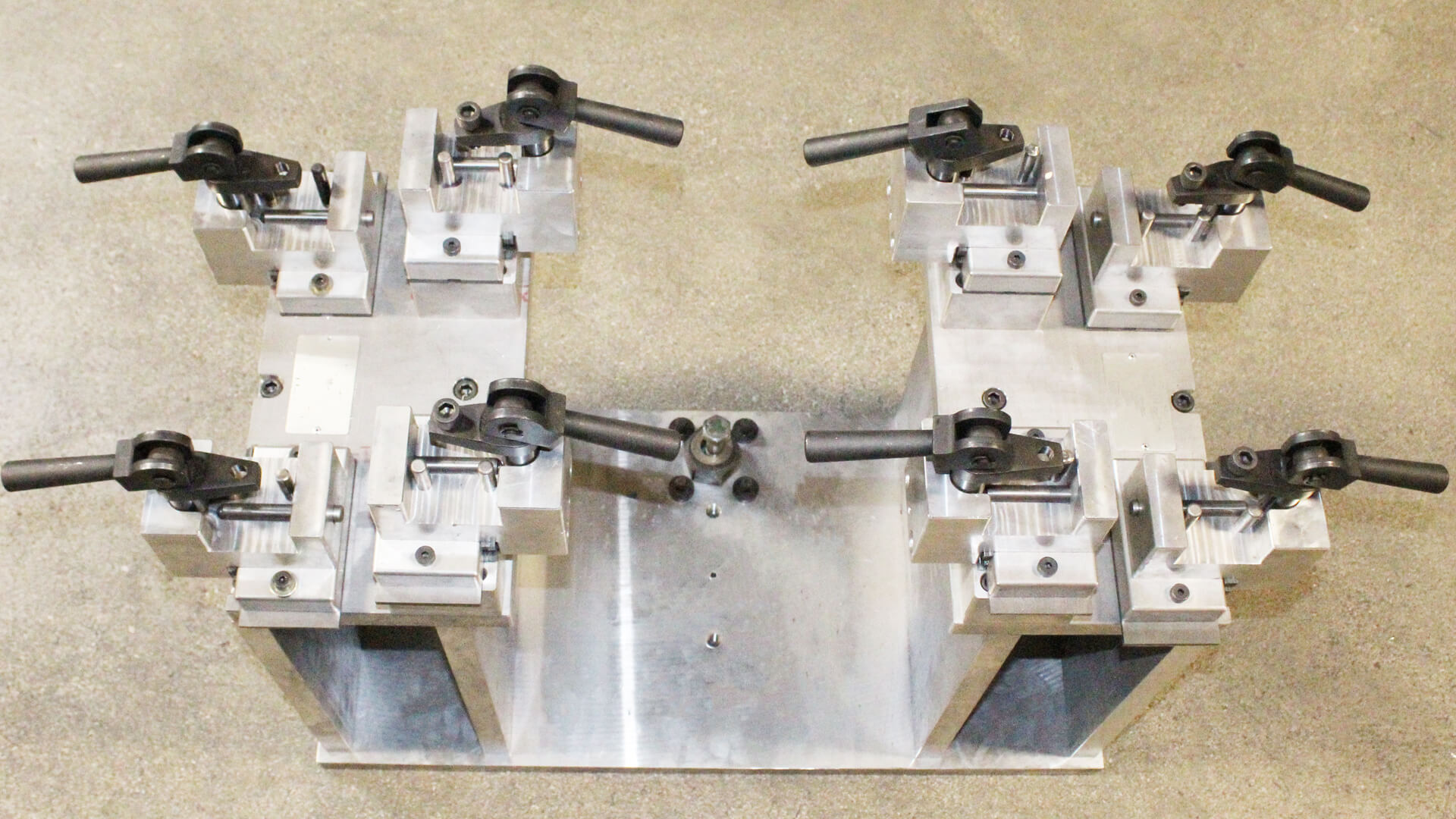

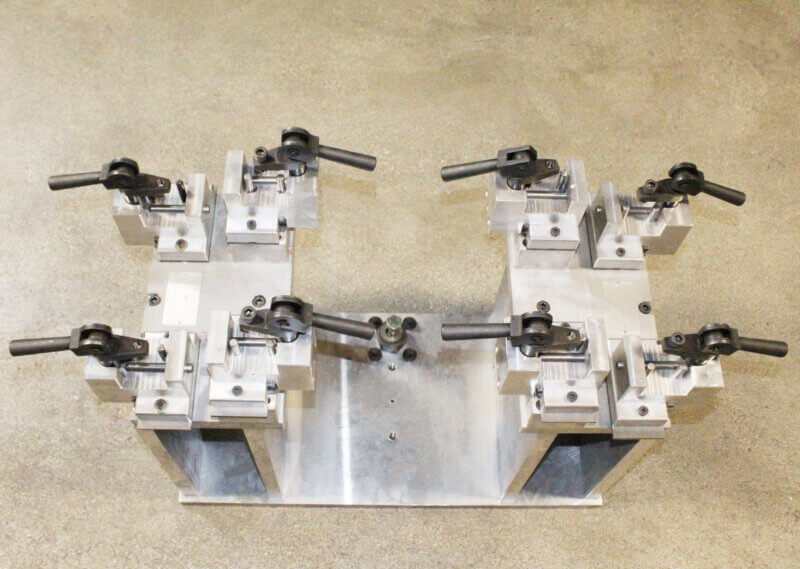

Fixture 2

Professionally designed and built production weld fixture, a must for consistent production in any significant quantities.

Professionally designed and built production weld fixture, a must for consistent production in any significant quantities.

- Designed in CAD, with input from welders in the shop

- Built with standardized shim packs to allow for adjustment during product development. Welded parts move … plan for it!

- Standardized components, kept in inventory or readily available for purchase online

- Built with stress relieved or otherwise stable materials

- Calibration, ownership and inventory tags attached for ongoing management and maintenance

Not to be overly critical of Fixture 1. It took someone with creativity and talent to create such a work of art. Unfortunately, like most works of art, it’s not the best tool if you’re goal is to achieve consistent quality, cost and delivery over the life of a product.