Precision Metal Fabrication: The Hidden Foundation of AI

Why Precision Metal Fabrication Matters

When people talk about artificial intelligence (AI), the focus usually falls on algorithms, big data, and computing power. But what often gets overlooked is the physical world that makes all of this possible. Behind every AI breakthrough is a foundation built on precision metal fabrication that supports and enables AI infrastructure.

From the racks that hold servers to the tubing that manages liquid cooling, fabricated components are the hidden backbone of AI infrastructure. Without repeatable, reliable, and exact parts, even the most advanced AI systems can’t function at their best. Precision metal fabrication is what transforms bold ideas into systems that can actually work.

AI Runs on Hardware, and Hardware Runs on Fabrication

AI is often seen as digital and abstract, yet its success is rooted in the physical world. From racks and processors to edge devices, every system depends on precision-engineered fabrication. That reliance shows up in several critical areas of AI infrastructure:

Server Racks & Frames: These structures hold thousands of pounds of computing equipment. Precision metal fabrication ensures they are stable, dimensionally consistent, and optimized for airflow. Even small deviations in alignment can restrict cooling and reduce the efficiency of critical hardware.

Cooling Systems: AI workloads generate enormous heat. To prevent failure, many systems now use liquid cooling with manifolds, skids, and tubular assemblies. If a bend angle is off or a weld is inconsistent, the system risks leaks or restricted flow. Data center energy demand is already consuming about 4.4% of U.S. electricity and is projected to rise further, highlighting the need for precise cooling and power infrastructure (energy.gov).

Protective Enclosures: AI systems often operate in demanding environments: on factory floors, in hospitals, or inside autonomous vehicles. Sheet-metal housings fabricated to exact tolerances provide the shielding needed to protect sensitive electronics from dust, vibration, or impact.

In each of these cases, metal fabrication doesn’t just support AI infrastructure—it makes it possible.

Why Precision Equals Predictability for AI

Artificial intelligence thrives on predictability. To process data consistently, AI requires hardware built to exact specifications. Without it, performance breaks down. Precision metal fabrication establishes the foundation for predictable AI performance, particularly in the areas of:

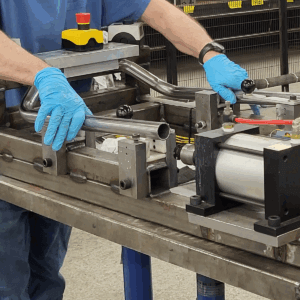

- Repeatability: AI systems like robotic arms or automated inspection cameras depend on precision mounts and housings. A slight variation in placement or angle can throw off calibration and reduce accuracy. Consistent fabrication ensures that every part performs identically, cycle after cycle.

- Reliability: Downtime is costly. For AI data centers, even a few minutes of unplanned outage can translate into millions of dollars in lost productivity. Precision-fabricated racks, tubing, and assemblies reduce the risk of failures and the maintenance burden that comes with poorly made components.

- Performance: AI systems are only as good as their weakest link. Smooth finishes that reduce friction, proper alignment that prevents air blockages, and structural integrity that supports heavy loads all contribute to system performance.

For industries investing billions into AI, precision isn’t a nice-to-have, it’s a requirement.

Fabrication and AI: A Two-Way Street

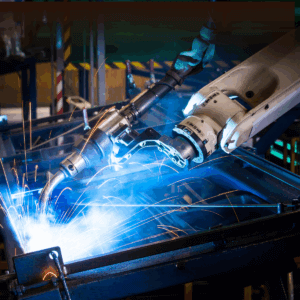

The relationship between AI and metal fabrication works in both directions.

- AI Relies on Fabrication: From data centers to autonomous vehicles, AI systems demand a baseline of consistent, high-quality parts. Without it, AI cannot deliver accurate, dependable results.

- AI Improves Fabrication: AI tools are also reshaping fabrication itself. Machine-learning models can analyze data from sensors on CNC tube benders, presses, and welding cells to predict tooling wear, detect quality deviations, or simulate part geometry before a single bend is made.

This feedback loop creates a powerful cycle: fabrication enables AI, and AI advances fabrication. But it’s important to remember that the cycle begins with high-quality, precisely fabricated components. Without that foundation, AI systems are working on unstable ground.

Real-World Examples of Fabrication in AI Infrastructure

While core infrastructure like racks and cooling makes large-scale AI possible, precision metal fabrication also enables the practical use of AI in the field. These applied examples show how critical accuracy and uniformity are beyond the data center:

-

Robotics: AI-powered robotic arms in manufacturing rely on mounts and housings fabricated within tight tolerances. Even minor misalignments can result in cascading errors across a production line.

-

Autonomous Vehicles: From brackets that hold LiDAR sensors to tubular assemblies that form lightweight frames, precision fabrication ensures vehicles gather reliable data for safe navigation.

-

Medical Devices: AI-assisted imaging or diagnostic equipment depends on precision-fabricated housings and supports that protect sensitive sensors and electronics in high-stakes environments.

Building Confidence in Tomorrow’s AI Systems

As AI adoption accelerates across industries, the demand for dependable precision metal fabrication will only increase. Every new system requires a foundation of components that are accurate, consistent, and built to withstand demanding conditions.

At Leonhardt Manufacturing, we understand that what we build today forms the hidden foundation of tomorrow’s AI systems. With decades of experience in precision tube bending, welded assemblies, and cosmetic finishing, we provide the reliability and consistency that advanced infrastructure demands.

Because for us, it’s not just metal fabrication, it’s the art of building confidence in the systems that shape the future.