Are you paying enough for tooling?

The upfront costs and risks associated with spending money on tooling are usually easy to quantify. The ongoing, perpetual costs of poor-quality tooling are often less well-understood. Its effect on quality and delivery can be the proverbial “death by a thousand cuts.”

Here are 5 questions every buyer should ask their suppliers before evaluating tooling costs:

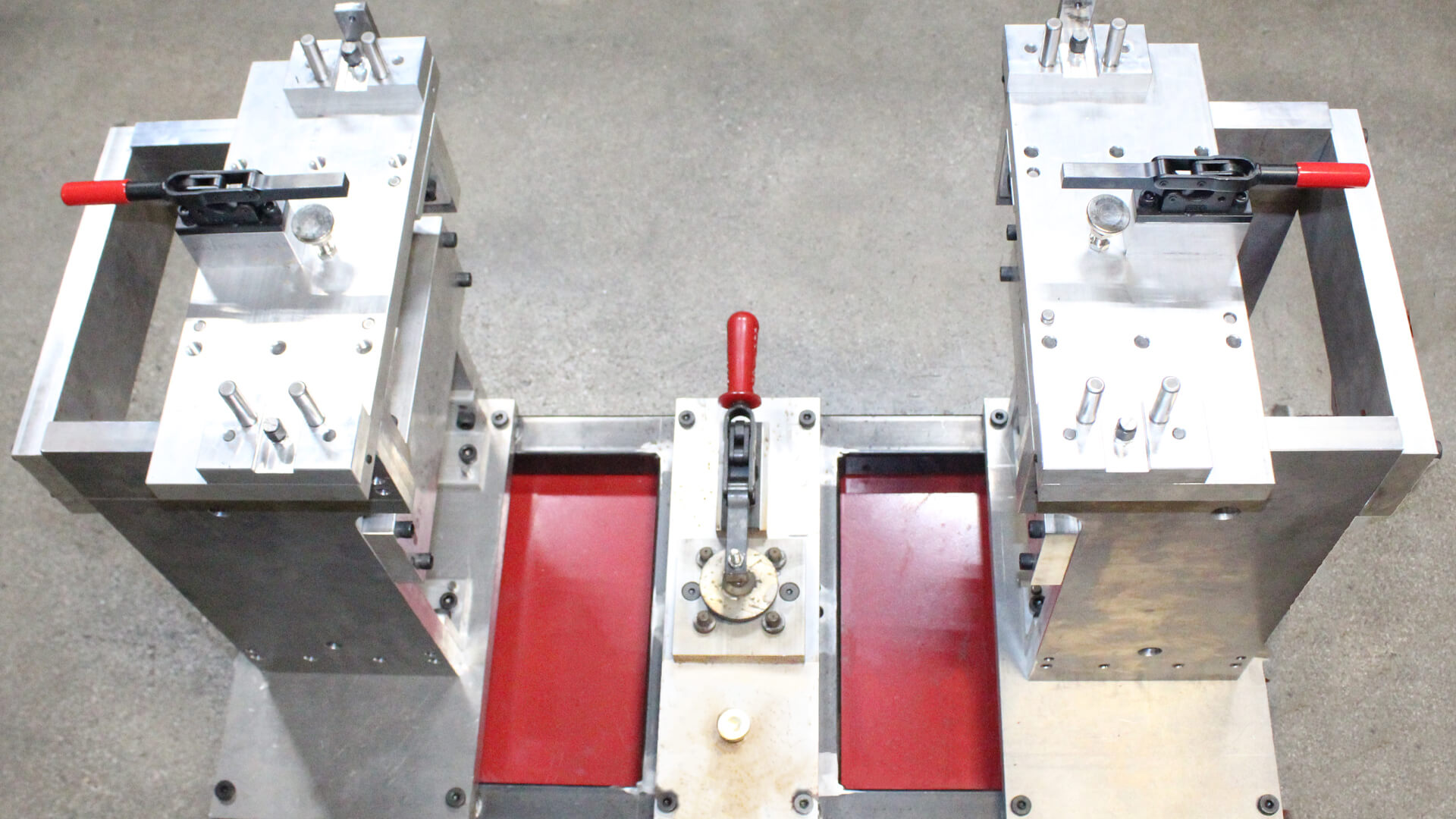

- Is the tooling professionally designed and built by tooling experts, or is it something tacked together “on the fly” by welders in the shop?

- Does your supplier have tooling and fixtures specs, assuring that proper materials, best practices and standard components will be used?

- How will the tooling be certified, calibrated and maintained?

- Are part-to-part variation, future design changes, material and process tolerances, and operator capability considered in the tooling design? Is adjustability built-in, or an afterthought?

- What are the potential consequences to your project associated with poor quality tooling? Late deliveries? Line stoppage?

When looking for a manufacturer, consider one that has in-house tooling capabilities as one of its key competitive advantages.

Check back in the coming weeks as we go through these steps in more detail here on the blog.

In the meantime, let us know how we can help with your company’s next project.