SHEET METAL FABRICATION

FLAT AND FORMED METAL PARTS FOR ASSEMBLIES OR STAND-ALONE SOLUTIONS

Home / Capabilities /

At Leonhardt Manufacturing, our sheet metal fabrication capabilities are designed to strengthen and complement our core services in tube bending, tube fabrication, decorative finishes, and sub-assemblies.

When your parts call for both formed tubes and sheet metal components, we deliver a fully integrated solution that streamlines production, ensures a precise fit and finish, and keeps your project on schedule.

We also offer stand-alone sheet metal fabrication for brackets, mounting plates, panels, and other components delivering the same quality, tight tolerances, and responsive service.

Sheet Metal Capabilities

Our in-house equipment and skilled team produce precision sheet metal parts that support tubular weldments with connection points, reinforcement, and mounting functionality, or serve as independent components for stand-alone projects.

Our Sheet Metal Services Include:

-

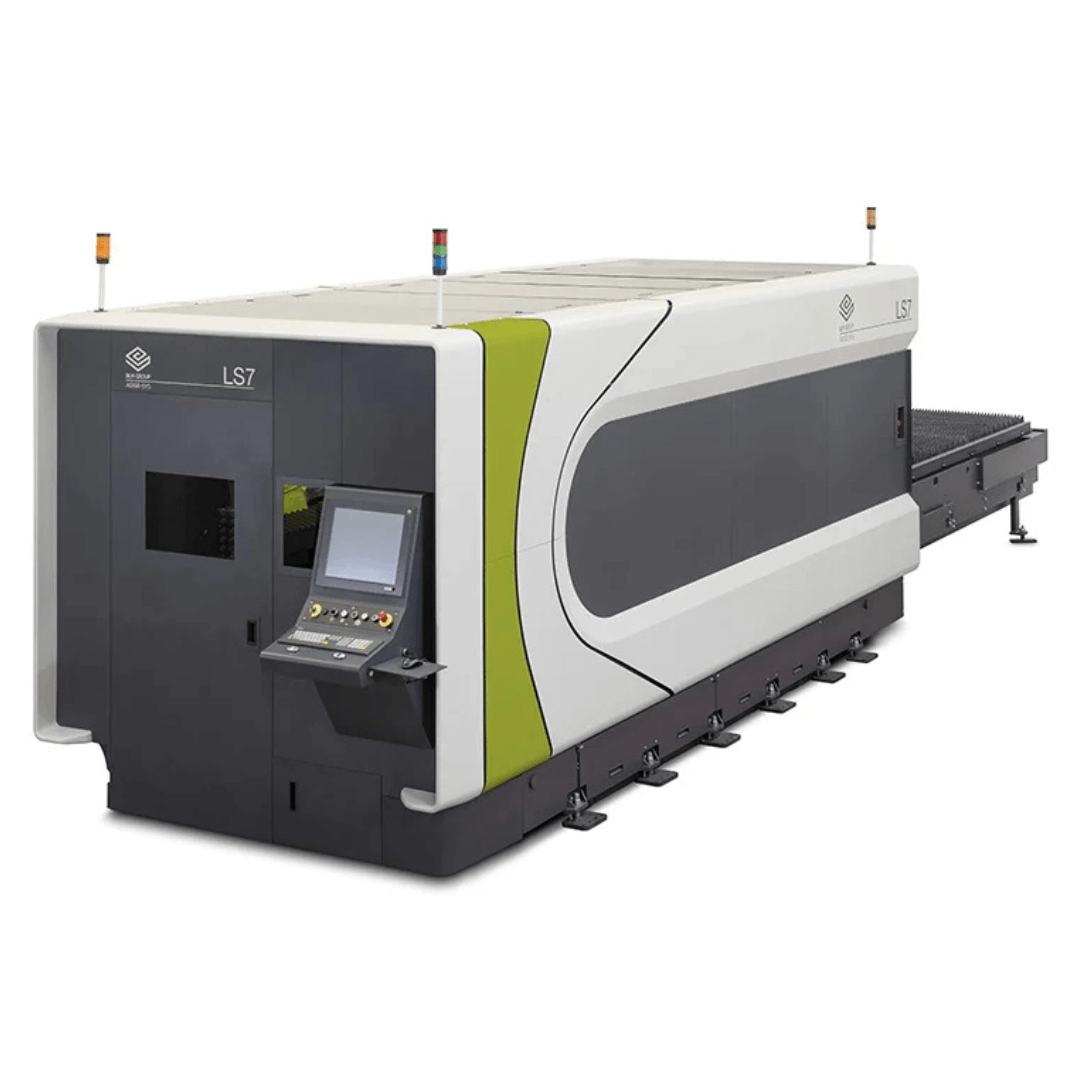

Laser cutting (thickness from 1/8″ to 1″)

-

CNC press brake forming

- Precision machining, drilling, milling, & chamfering

-

Punching and notching

-

Edge deburring and finishing

-

Light assembly and part integration

Every part is manufactured to meet tight tolerances and cosmetic requirements, ensuring consistency whether integrated with tubes or supplied on its own.

Integrated and Stand-Alone Solutions

At Leonhardt, we understand that every project is different. That’s why our sheet metal fabrication is built to be flexible – seamlessly integrated with tube assemblies when you need a complete solution, or delivered as stand-alone components when your project calls for independent parts.

Either way, you get the same benefits: repeatable precision, cosmetic quality, and the confidence of working with one trusted partner who can adapt to your needs and keep your production moving forward.

THE LEONHARDT ADVANTAGE

- Work to Customer Specifications Regarding Materials, Tolerances, Performance, Durability, and Cost.

- 95,000 Square Foot Manufacturing Facility

- Compound Tube Bending / Multi-Radius and Variable Radius CNC Tubing Bending

- CNC Robotic MIG Welding & TIG Welding with ASME Certified Welders

- Metal Stampings and Sub-Assemblies

- Lean Manufacturing Processes for High Efficiency & Cost Control

- Supply Chain Management Services to Consolidate Processes and Reduce Total Cost

DELIVERING SOLUTIONS

TO COMPANIES LOOKING FOR:

-

Complex, high-precision metal fabrications

-

Consistent quality across repeatable production runs

- Exacting Product Tolerances

-

Cost control through lean practices and smart supply chain integration

-

Just-in-time delivery and flexible production scheduling

-

A partner who understands the pressure to meet aggressive timelines, tight tolerances, and evolving product requirements

FEATURED JOB STORY

AME Features Tour of Leonhardt Manufacturing’s LEAN Facility

Leonhardt Manufacturing was proud to be a featured stop for the Association for Manufacturing Excellence tour showcasing their excellence in LEAN manufacturing techniques including Value Stream Mapping, cellular manufacturing, Kanban, Poka-Yoke, and visual management.