OUTSOURCED TUBE BENDING WELDING & METAL FABRICATION SERVICES IN THE US

Home /

Bus Rail Seating

Partnering with Leonhardt Manufacturing to reshore your product development and manufacturing allows you to reduce time and cost while focusing your attention on your core competencies. We work with you to manage the entire production process and deliver a completed product.

A leading rail car seat manufacturer needed a tube bending supplier with the capability of delivering complex bent and welded stainless steel tubular assemblies on a just in time basis. This work requires strict QA for both cosmetic and structural accuracy. Leonhardt developed custom tooling and fixtures and worked with the client’s team of engineers, technicians and product managers from prototyping through production.

By partnering with Leonhardt, the company has increased its speed to market and boosted overall capacity.

Check out our tube bending video library.

![]()

Our Service Offerings

Leonhardt is a world-class manufacturer specializing in highly decorative tubular products and tubing fabrications. Our tubular products and welded assemblies combine CNC bent tubes, metal stampings, machined parts, plastic injection molded components and a variety of finishes.

We work with you to reduce management attention, manufacturing time and total cost by reshoring product or component development, allowing you to focus on expanding your core competencies and internal strengths.

We deliver a complete product manufacturing solution to companies who need fabricated components at production quantity levels. Outsourcing product development to Leonhardt reduces expenses through lean manufacturing, JIT, delivery, and streamlined supply chain management.

Range of Capabilities

Core Capabilities

- CNC Tube Bending

- Tube Fabrication

- MIG and TIG Welding

- Robotic MIG Welding

- Aluminum Welding

- Design for Manufacturability

- Brazing

- Metal Stampings

- Polishing & Chrome Plating

- Sub-Assemblies

Value Added Core Competencies

- Prototype & Development

- Design for Manufacturability

- Outsourced Manufacturing

- Supply Chain Management

- Lean Manufacturing

- Cost Containment

Materials & Metals

- Aluminum

- Steel

- Stainless Steel

- Galvanized Steel

- Cold Rolled Electric Weld

- DOM Tubing

Our 95,000 square foot facility features specialized workers and equipment designed to fabricate, manufacture and finish high quality metal products and components with accuracy and efficiency.

Have a project in mind?

Tell us about your product to see how we can pull our full range of capabilities together to solve your organization’s needs through full, end-to-end outsourced manufacturing services.

Why Outsource your Manufacturing to Leonhardt?

Reshoring the manufacturing of parts or components to Leonhardt allows you to significantly decrease your production costs and increase focus on your core business, enabling ownership and expertise of internal processes that are core to your business.

We work with you to manage your entire production process and deliver a completed product that you can focus on taking to market.

Key Benefits of Outsourcing Product Development

Reduce operating and labor costs

Align company focus on core competencies

Increase quality of products through stabilization of cost and design

Fuel innovation through access to world class technology and expertise

Increase management of supply channels

How We Become Your Outsourced Manufacturing Partner

Understanding a company’s application and specifications is critical in assuring Design For Manufacturability and Assembly (DFMA), and Value Analysis / Value Engineering (VA/VE) for custom parts. As a contract manufacturer, Leonhardt continuously works to improve your products through innovative manufacturing processes, product design enhancements, quality control, and supply chain management refinement.

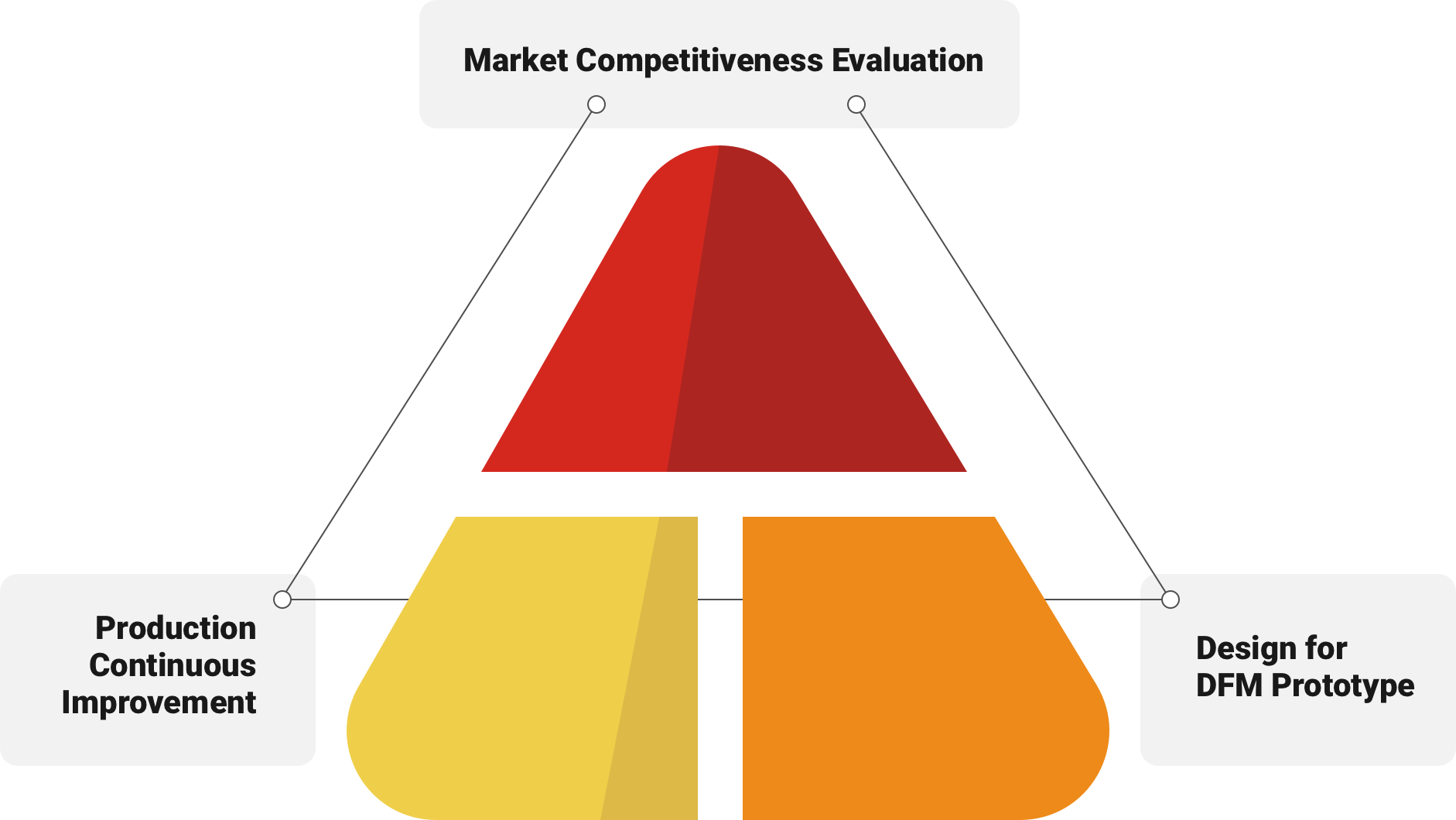

Our Reshored Manufacturing Process

1

Product design vs.

market need

We’ll review the part or program for market competitiveness in terms of appearance and durability.

2

Product design vs. manufacturability

Next, we’ll review prototype design for manufacturability (DFM).

3

Production Continuous Improvement

We’ll determine the best possible tolerance, time and total cost (TCO).

Outsourced Manufacturing Success

Industry leaders count on Leonhardt Manufacturing’s expertise and diverse manufacturing knowledge to make better products. Whether it’s working with aftermarket motorcycle parts manufacturers, global furniture designers, or a leading manufacturer of infrastructure and flow control products to improve the design of one of their residential water meters we have the expertise and skills to make our partners more successful.

How Can We Help?

Leonhardt works with you to reshore product or component development, allowing you to focus on your core competencies and decrease capacity and cost. Through our range of capabilities and our outsourced manufacturing process, we become an end-to-end partner to your organization. Fill out the form below to connect with a manufacturing expert so we can learn more about your product.