The Manufacturer’s Guide to On-Time Delivery (OTD)

Supplier Reliability • On-Time Delivery

How Reliable Processes Create Reliable Shipping

On-time delivery in manufacturing is one of the strongest indicators of a supplier’s reliability. More than a single KPI, on-time delivery affects production stability, launch timing, cash flow, and your reputation with customers. This guide explains how to define OTD clearly, measure on-time delivery in manufacturing, diagnose late shipments, and strengthen your supply chain with reliable, repeatable processes.

The sections below highlight six practical areas to review with your team and suppliers. Keep the main steps in view as a roadmap and expand the dropdowns to see checklists, questions, and tools you can apply directly in your day-to-day work.

Step 1: Define What “On Time” Really Means for Your Operation

Every organization uses the phrase “on time,” but not everyone defines it the same way. Before you can measure or improve OTD, you need a clear, shared definition that matches your production reality and your customers’ expectations.

Questions to Clarify Internally

- Do we define “on time” as the promise date, the required date, or the dock date?

- Are partial shipments considered “on time,” “late,” or tracked separately?

- Do we measure OTD by line items, POs, shipments, or scheduled releases?

- How do we handle customer-approved changes that move dates?

Step 2: Measure Your Current OTD Performance

Once you’ve defined “on time,” you can start measuring it consistently across your supplier base. The goal is not just to generate a percentage, but to understand the long-term patterns behind on-time delivery in manufacturing and see which partners stabilize your production and which introduce risk.

Core OTD Metrics

- Overall OTD % by supplier, part family, commodity, and program

- Late delivery frequency (how often a supplier misses a date)

- Average days early/late versus the promise date

- Expedites per month (how often you have to “chase” orders)

- Schedule stability (how often ship dates move after the PO is accepted)

Step 3: Evaluate Suppliers with an OTD Scorecard

A good OTD percentage doesn’t always tell the full story. Some suppliers hit dates but constantly require chasing, move promise dates, or create instability upstream. A simple scorecard helps you evaluate supplier performance holistically.

Supplier OTD Evaluation Grid

| Criteria | 1 | 3 | 5 |

|---|---|---|---|

| Delivery consistency | Unpredictable | Generally stable | Exceptionally reliable |

| Communication | Reactive | Mixed | Proactive & early |

| Capacity planning | Overloaded / unclear | Partially controlled | Well-documented & controlled |

| Material readiness | Frequent shortages | Occasional gaps | Consistently prepared |

| First-pass quality | Rework common | Occasional issues | Extremely stable |

Score interpretation:

22–25 = world-class, strategic partner; 17–21 = stable, review periodically; 12–16 = potential risk, dig deeper; <12 = high-risk supplier for time-sensitive work.

Suppliers with strong ISO 9001 quality assurance systems typically maintain more consistent on-time delivery because their first-pass quality is more stable.

Download Supplier OTD Scorecard Template

Step 4: Diagnose Why Deliveries Are Late

Late shipments often reflect systemic issues, not isolated incidents. Identifying root causes helps you determine whether a supplier is overwhelmed, poorly managed, or simply not aligned with your expectations. A simple tool like the 5 Whys can help uncover the underlying issue, and from there, targeted diagnostic questions can clarify what actually caused the delay.

Root-Cause Questions

- Was the delay due to material, capacity, quality, engineering changes, or logistics?

- Did the supplier flag the issue early—or only after missing the date?

- Is this a recurring pattern on certain part numbers or programs?

- What corrective actions were taken? Did they prevent recurrence?

After identifying the primary cause of the delay, record the findings in a simple worksheet to support corrective action.

Step 5: Look Behind the Number – Why Strong OTD Doesn’t Happen by Accident

On-time delivery is the outcome of dozens of connected processes working in sync. The most reliable suppliers build OTD into their systems, not just onto a scorecard. In a stable operation, production, planning, and quality share a common goal: protect the promised ship date without sacrificing standards.

Key Factors That Drive Strong OTD

- Robust material planning: Early purchasing and disciplined inventory control prevent shortages.

- Accurate scheduling & capacity control: Jobs are backed by realistic time, resources, and staffing.

- Aligned production flow: Material moves cleanly from raw stock to finished assembly without bottlenecks.

- Stable, repeatable processes: Standardized bending, fabrication, and finishing keep cycle times predictable.

- Quality at each step: High first-pass yield prevents rework and last-minute schedule chaos.

- Integrated assemblies: Managing multiple fabrication steps under one roof reduces handoffs and risk.

- Clear, proactive communication: Early updates on approvals, materials, and schedule changes prevent surprises.

Step 6: Build OTD Expectations into RFQs and Supplier Reviews

OTD should be part of how you select, qualify, and maintain suppliers—not just something you check after parts arrive. The more clearly you define expectations at the RFQ stage, the easier it is to align operations on both sides. Building expectations for on-time delivery in manufacturing into your RFQs creates alignment from day one.

Questions to Ask During RFQs

- “How do you calculate and track your on-time delivery performance?”

- “What scheduling tools or systems do you use to manage capacity?”

- “What is your process when something threatens a ship date?”

- “Do you control all fabrication steps internally, or rely on outside processors?”

- “What is your first-pass yield rate on comparable parts or assemblies?”

These questions help reveal whether reliability is built into their culture or only into their sales pitch.

Turning OTD into a Competitive Advantage

On-time delivery is not simply a metric, it’s a reflection of how a manufacturer plans, manages, and executes. When you define OTD clearly, measure it consistently, and analyze the systems behind the number, you gain a powerful tool for improving supplier performance and building a more resilient supply chain.

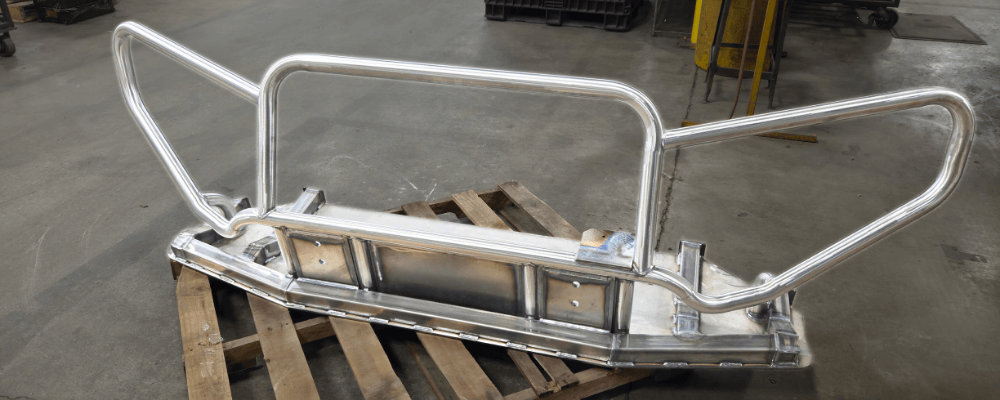

At Leonhardt Manufacturing on-time delivery is engineered into the way we operate from disciplined scheduling and stable processes to integrated assemblies and responsive communication. This foundation helps customers protect their timelines and maintain confidence in their production flow.