Blog

Home /

Tube Bending Design Guidelines for Better Production

Even well-functioning tube parts can be costly to produce if the design isn’t optimized. From tight bend radii to vague specs, learn five common design flaws that slow production—and how to fix them without sacrificing performance.

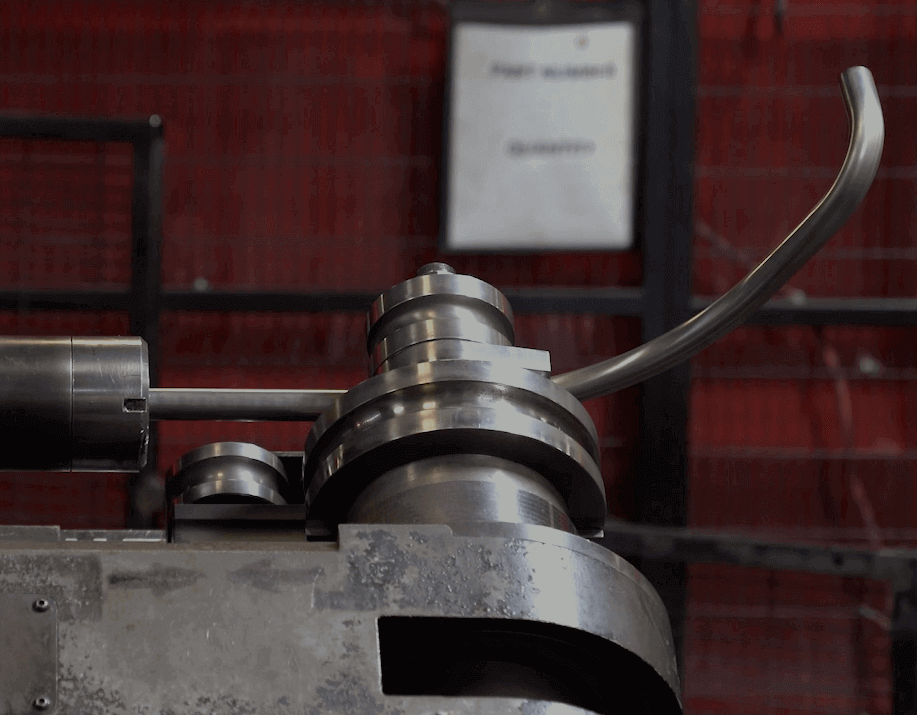

Ensuring Repeatability in Tube Fabrication

Repeatability in tube fabrication is essential for consistent quality, especially with complex or cosmetic parts. Learn how we control every detail to deliver precision in every run.

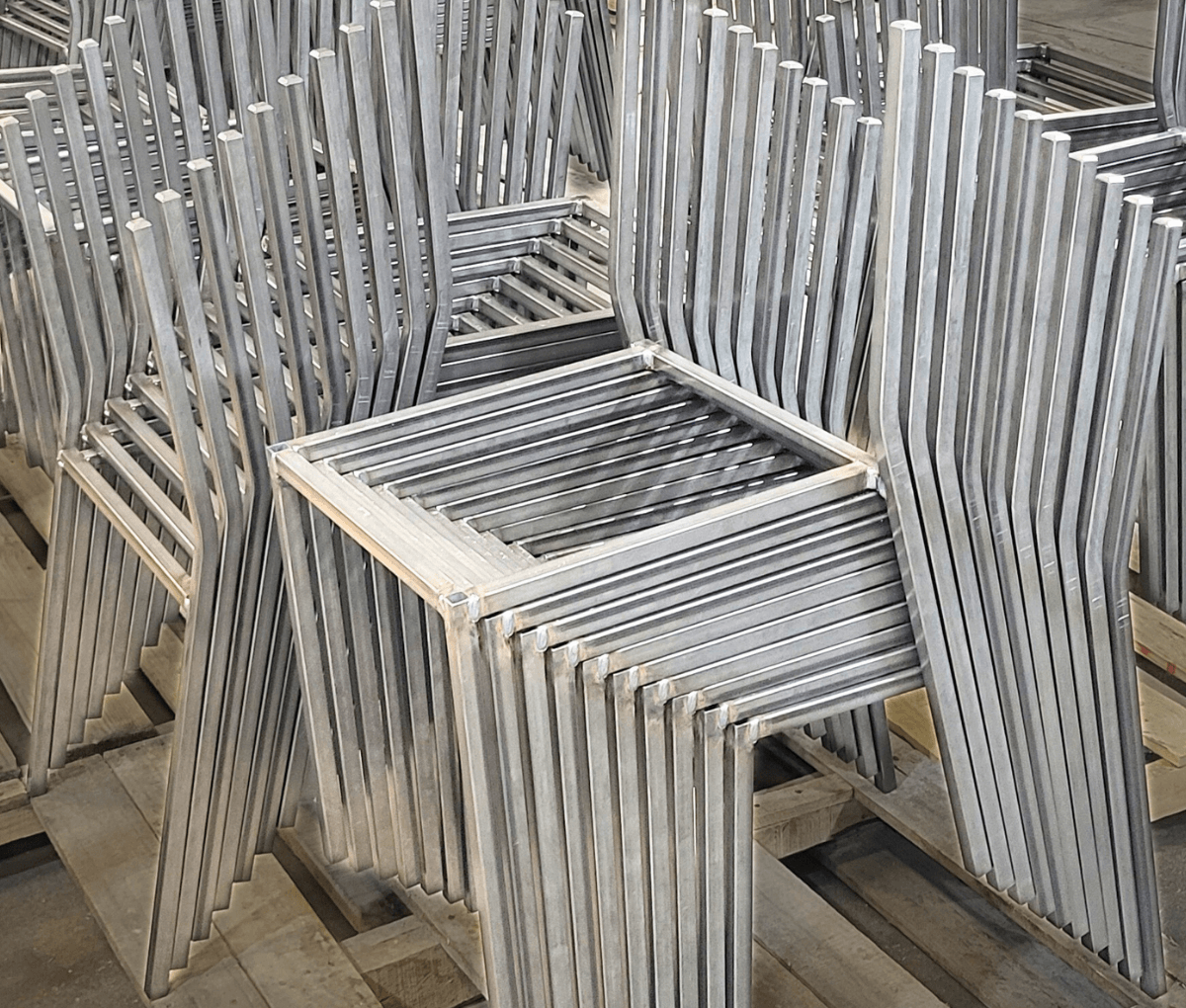

Getting Complex Tube Fabrication Right

Discover what makes tube fabrication complex—from tight radii and multi-plane bends to material behavior and cosmetic finishes—and why repeatability is the ultimate challenge.

Ensuring On-Time Delivery: Key Practices in Contract Manufacturing

Effective management of lead time and delivery schedules is crucial for successful project outcomes. Discover how key strategies can help minimize delays and ensure high-quality, on-time delivery.

Cost Management in Contract Manufacturing

In contract manufacturing, managing costs is crucial for maintaining quality and profitability. This guide explores key areas: understanding cost components, implementing cost-saving strategies, and evaluating ROI for metal tube bending projects. By understanding these aspects, clients can make informed decisions for successful partnerships.

ISO 9001: Elevating Quality Assurance in Contract Manufacturing

Quality control is paramount for contract manufacturing success. ISO 9001 certification ensures adherence to standards and customer needs, guiding manufacturers towards excellence and fostering lasting partnerships.

Choosing the Right Contract Manufacturer: A Guide for Success

In today's dynamic business world, outsourcing manufacturing processes has become essential for companies aiming to optimize efficiency, cut costs, and concentrate on core competencies. Explore essential factors in selecting the ideal contract to find your perfect partner to maximize business potential.

Contract Manufacturing for Tube Bending

Unlock the potential of contract manufacturing for tube bending with our beginner's guide. Learn how this model can save costs, provide expert assistance, and offer unmatched flexibility for your projects. Discover the steps to get started and overcome common challenges, ensuring your venture into contract manufacturing leads to success.

Material Selection: Beyond the Bend in Tube Fabrication

Material selection in metal tube bending is a crucial factor that affects everything from mechanical properties to corrosion resistance, making it essential for industries spanning from furniture design to vehicles.

Ensuring Precision Bent Parts: Romer Arm & Bend Check Fixtures

In the realm of precision manufacturing, the quality of bent parts is paramount across industries like aerospace and automotive. Learn how the Romer Arm and Bend Check Fixtures boost precision and efficiency in manufacturing. Discover when to use each method and how they can work together to guarantee top-notch results.